Brand Name:QiCheng

Place of Origin:Foshan, GuangDong of China

MOQ:1SET

Lead Time:40 Days

Loading Port:Foshan, China

Payment:T/T,L/C, 35% down payment, full payment be done before shipping

Trade Term:FOB or CIF

Installation & Commissioning:YES

Feature

1.At 450℃ temperature t can work stably to meet theperformance requirements of high temperature, no matteigh temperature metal coating or compositing of other

twof high temperature composite base materials can be easi.

2.Due to its characteristic and excellent performance, thesurtace temperature can be precisely controlled within + Caccording to the requirements and both the

temperature andtemperature changing gradient can be controled accordingto the special process requrements to ensure the processingquality, deducing the reject

rat.

3.Low energy consumption, less maintenance. energy savingeffect is remarkable. Compared with the traditional roller. thepower consumption of electromagnetic

heating roller can bereduced by 30% or more, spang the complex heating pipelineacilities, which greatly reduce the energy consumption.

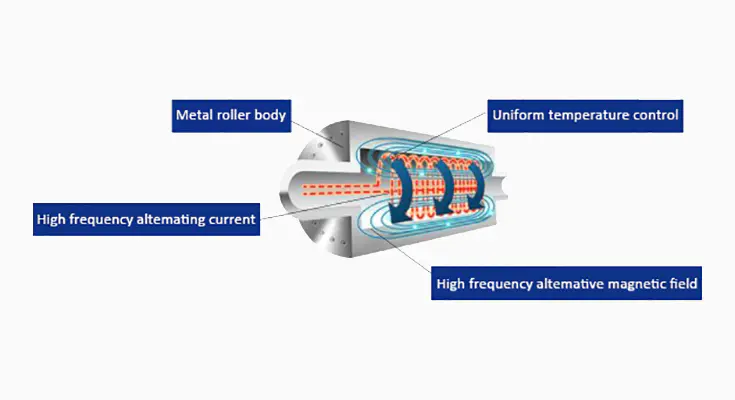

4.Electromagnetic heating rollers using electromagnetic induction eddcurrent technclogy.

5.Electromagnetic heating rollers can be customized to meet thecustomers demand.

6.Eectromagnetic heating rollers can replace conventional heatingequipmen(Customized specifications are available.

7.Unique design, advanced technology, convenient and eas)maintenance5 No noise pollulion, eco-fnendly and energy saving about 30-40%6. There is no evaporation(

oil-free and water free)during heatingmaking the production environment very clean.

Widely used in: Drying oven production and remaking(electromagnetic heating). Carbon fiber inflation axis and ordinary axis (electromagneticheating). Hot forming(electromagnetic heating). PVC plastic flooring tie extrusion, calendering, coating, laserplastic laminating, aluminum sheet processing, medical packingLithium batteries, canbon fiber production equipement etc. This electromagnetic heating technology has overcomes the slowheating of radit onal heating rollers and uneven surface temperature.poor resistance to high temperature, thus heating time and heating rateis greatly increased, espec ally the energy saving effect is remarkabe-about 30-40%. Because there is no conventional oil evaporation duringheating process, cleanness of environment have been improvedgreatly. |  |

Basic Information

| Part Name | Electromagnetic heating roller | Conventional heating roller |

| Heating up time | 30-40min | 60min (above) |

| Heating up speed | 5℃%/min | 3℃%/min Appr. |

| Temperature eveness | ±1℃ | |

| Cooling down time | Just turn off | After tum off6-10h |

| Energy conservation | 30-40% | |

| Pollution | no | Oil leakage |

| Lifespan | 1000h above | |

| Operating Temperature Range | 0-450℃ | 0-250℃ |