-Small prototype

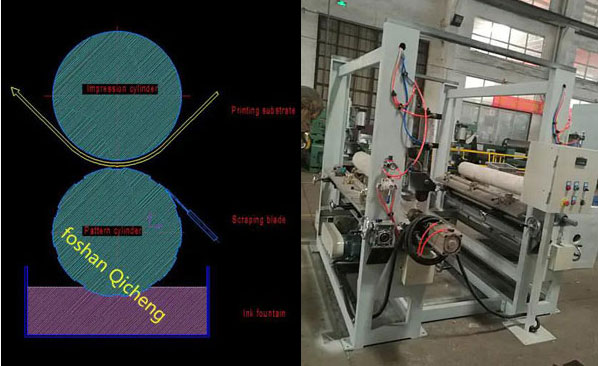

For gravure printing is used to do the testing for the design patters, or

for testing the inks, many customers require this machine together with

the entire production line

Gravure printing is most suitable for the big quantity printing requirements, like as the wall covering material, table cloth, packing material and so on.

Among all the printing style, Gravure printing still is the best and great performance in the printing quality.

Mostly, rotogravure printing always working together with laminating, foaming, embossing, crown printing, gilding, screen printing, slitter, to meet the different needs in decorative and packing.

Apply suitable for the material of paper and any plastic film.

Different raw material decided the different design for the processing, the width, the thickness, the draftability, thermostability...

Width of 1M tension value table(kgf)

| Material | Sending | Feeding | Impression | Winding |

| Glass paper | 10-15 | 13-18 | 13-20 | 6-10 |

| Polypropylene | 8-13 | 10-15 | 10-18 | 6-10 |

| Stretched polypropylene | 5-10 | 7-12 | 10-15 | 4-8 |

| Paper | 15-20 | 20-25 | 20-25 | 12-25 |

Plastic film drying temperature

| 0-20% | 30%-70% | 80%-100% |

| 80m/min | 40±10℃ | 50±10℃ | 60±10℃ |

| 120m/min | 40±10℃ | 60±10℃ | 70±10℃ |

| 160m/min | 45±10℃ | 60±10℃ | 75±10℃ |

| 200m/min | 45±10℃ | 60±10℃ | 80±10℃ |

Workshop temperature and humidity affect the printing quality.

Keep the temperature in18-23C, humidity in50%-60% are optimum.

Keep the workshop clean, and air circulation